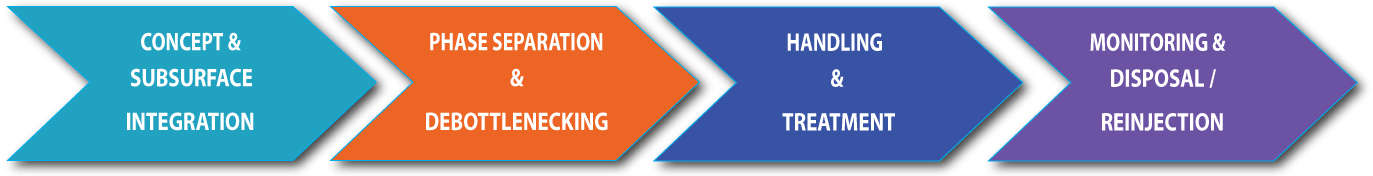

Separation Systems

- Project Mgt

- Commercial Strategy

- Data Gathering

- Site Inspection

- Conceptual Design

- Studies

- Project Mgt

- Commercial Strategy

- Data Gathering

- Site Inspection

- Conceptual Design

- Studies

- Proposals

- Process Design

- R&D, Qualification

- Assembly & Skid Design

- Fabrication & Testing

- Proposals

- Process Design

- R&D, Qualification

- Assembly & Skid Design

- Fabrication & Testing

- Pumps

- Instrumentation

- Chemicals

- Consumables

- EPC

- Assembly & Skid Design

- Pumps

- Instrumentation

- Chemicals

- Consumables

- EPC

- Assembly & Skid Design

- Effluent Analyzers

- PWRI Subsurface Studies

- Pump Selection

- Well Completion Design

- Compliance Management

- Effluent Analyzers

- PWRI Subsurface Studies

- Pump Selection

- Well Completion Design

- Compliance Management

Separation Systems & Debottlenecking Technologies

- New build facilities

- CAPEX reduction with compact separation systems

- Production challenges needs innovative separation solutions

- Debottlenecking of existing process

- Increased processing capacity (IOR) adapt to new production profiles

- Reduce OPEX: due to chemical consumption, heating duty, or frequent maintenance

Conventional Separation Systems

With our high performance internals, your separator vessel can perform not just at its maximum capacity but also raising the efficiency beyond limits. These internals can increase the capacity & efficiency of existing production trains and new built vessels. Also new built vessels can be reduced in size compared to the conventional separators.

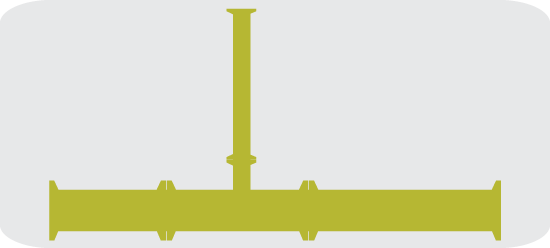

Inline Separation Systems

With the right combination of our InLine products, all separation challenges can be resolved and all your separation requirements will be met. Our inLine products (based on cyclonic and electrostatic technologies) are highly efficient and compact, allowing complete line phase separation on a pipe segment without the need of several large vessels.